Leave Your Message

In the world of automotive maintenance, a reliable Car Tire Changer is crucial. According to industry reports, around 23% of vehicle breakdowns relate to tire issues. This emphasizes the importance of having effective tools to manage tire changes. A well-functioning tire changer can enhance productivity, saving time and effort for professionals and DIY enthusiasts alike.

However, using a Car Tire Changer isn't always straightforward. Many mechanics face challenges during operation. Misalignment and improper use can lead to tire damage or safety concerns. In fact, a study by the Automotive Maintenance Association noted that improper tire installation contributes to 15% of tire-related accidents. This underscores the necessity of mastering the equipment's functions.

Focusing on best practices can prevent common pitfalls. Maintaining the Car Tire Changer is essential to ensure optimal performance. Understanding its components and limits allows for smoother operations. Yet, many users overlook basic maintenance, leading to inefficiencies. Investing time in learning effective techniques can make all the difference.

Understanding the operation of a car tire changer is crucial for effective use. This machine simplifies the process of changing tires, but it requires some skill. Familiarize yourself with the parts: the mount head, turntable, and bead breaker. Each part plays a role in changing tires efficiently. Watching instructional videos can help visualize these components in action.

Practice is essential. Sometimes, things won't go as planned. A tire might get stuck, or the bead may not seat correctly. It's frustrating, but these moments offer valuable learning opportunities. Adjust the pressure slowly and watch for any unusual behavior. Make note of your mistakes. This reflection can lead to improvement over time.

Safety is another key aspect. Ensure you're wearing gloves to protect your hands. Keep your workspace organized. A cluttered area increases the chance of accidents. While learning to use the changer, take your time to avoid damage to the tires or the machine. Precision beats speed in this task. Balancing accuracy and efficiency creates a smoother experience.

Operating a car tire changer comes with its own set of challenges. Safety should always be your top priority. Before you start, ensure you wear appropriate safety gear. Gloves and eye protection can prevent injuries from flying debris. Loose clothing can get caught in machinery. That’s a risk you don’t want to take.

Make sure the work area is clean and well-lit. Clutter can lead to accidents. Keep tools and tires organized. Check that the tire changer itself is in good working condition. Look for signs of wear or damage. Regular maintenance is essential. It’s important to read and understand the equipment manual. Skipping this step can result in improper usage and potential injury.

Always remember to secure the tires properly into the changer. A poorly fitted tire can cause the machine to malfunction. Take your time with this step. Rushing can lead to mistakes. Every action taken should be deliberate and careful. Inexperienced operators should seek guidance. Asking for help can prevent unnecessary accidents. Being mindful can save you time and trouble later.

When mounting a tire, precision is key. Start by deflating the tire completely. This creates less pressure on the bead. After that, inspect the rim and tire for any damage. Use a bead breaker to separate the tire from the rim. According to industry data, improper mounting can lead to safety issues. About 25% of tire failures are linked to incorrect installation.

Before placing the tire on the changer, ensure the machine is calibrated. Many tire changers have adjustable settings to accommodate different sizes. Incorrect settings can cause bead damage. Engage the tire onto the rim carefully. Remember, the expiration date on tire changers is often overlooked. Regular maintenance is crucial for longevity and safety.

As you work, listen for unusual sounds. They might indicate something is off. After securing the tire, inflate it slowly. Monitor the pressure closely. Over-inflation can cause the tire to burst, posing a risk to you and others. Each step is vital. Reflection on your techniques can lead to better practices over time. The right approach not only saves time but also enhances safety on the road.

Using a car tire changer effectively requires skill and attention to avoid damaging tires. When removing tires, start by inspecting the beads. Look for any debris or dirt. Cleaning them can make a big difference. Another essential tip is to ensure proper lubrication. Use a tire lubricant on the rim and tire. This prevents friction and makes the tire easier to remove.

Careful positioning is crucial. Place the tire correctly on the changer to avoid any misalignment. Misalignment can lead to pinched tires or damaged rims. Pay attention to the tools you use as well. A blunt tool can cause unforeseen damage. Remember, not all changers are equal. Sometimes, it’s easy to overlook minor adjustments, but they can lead to major issues.

When removing tires, go slowly. Rushing can mean disaster. Watch for the bead seating too. If a bead is not seated properly, you’ll have bigger problems. Know that mistakes can happen, and learning from them is part of the process. Keep practicing these techniques for better results in the long run.

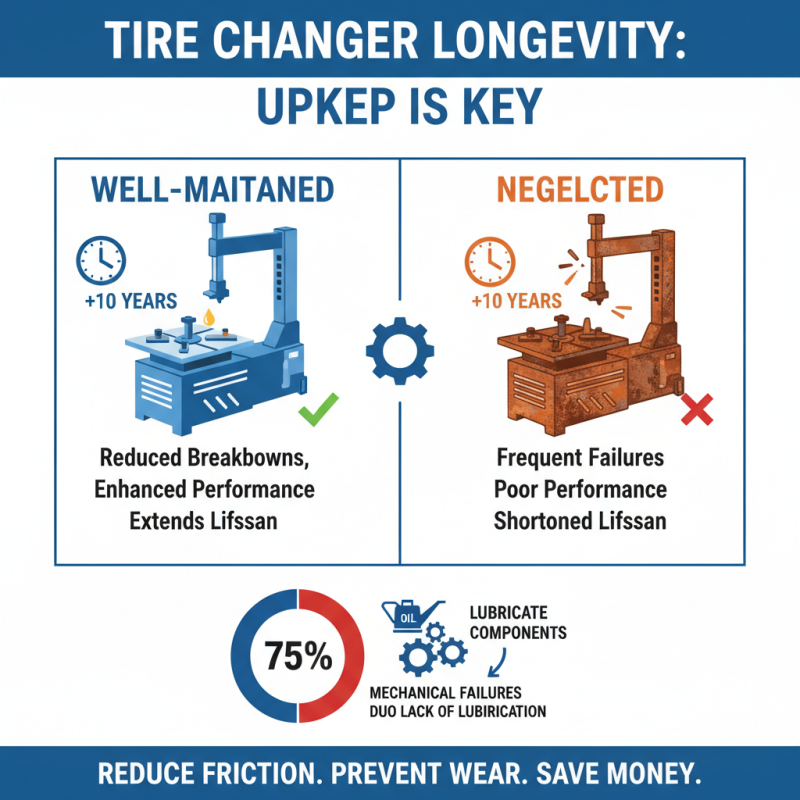

Maintaining your tire changer is crucial for its longevity and efficiency. Regular upkeep can reduce breakdowns and enhance performance. According to industry reports, a well-maintained tire changer can last over 10 years longer than one that is neglected. Keeping components lubricated is vital. This reduces friction and prevents wear. One study found that 75% of mechanical failures are due to inadequate lubrication.

Tip: Check the oil levels daily. Use the manufacturer’s recommended oils for optimal performance. Avoid mixing different types, as this can lead to problems.

Inspecting the tire changer regularly is essential. Look for loose bolts and worn parts. Even minor issues can escalate if ignored. In fact, nearly 30% of accidents in tire shops are linked to equipment failure.

Tip: Create a maintenance schedule. Following this can save time and money over time. Small fixes today can prevent big problems tomorrow.

Lastly, keep the area around your tire changer clean. A cluttered workspace can lead to accidents. Reports indicate that up to 40% of injuries in shops are caused by slips and falls. An organized environment enhances safety and efficiency.