Leave Your Message

Choosing the right equipment for construction or maintenance tasks can be challenging. One solution that stands out is the Mid-Rise Scissor Lift. This lift offers versatility and ease of use for various projects. Whether you need to reach high ceilings or perform overhead tasks, this equipment can meet your needs.

Using a Mid-Rise Scissor Lift effectively requires careful consideration of a few factors. First, assess the working environment. Is there enough space to maneuver the lift? Remember, these lifts have specific weight limits and height capabilities. A miscalculation can lead to safety issues or project delays.

Moreover, training is essential when operating a Mid-Rise Scissor Lift. Operators should understand the lift's controls thoroughly. They must also be aware of the terrain and potential hazards. Regular maintenance can prevent many issues, yet many users overlook this step. Taking these precautions ensures safer and more efficient operations.

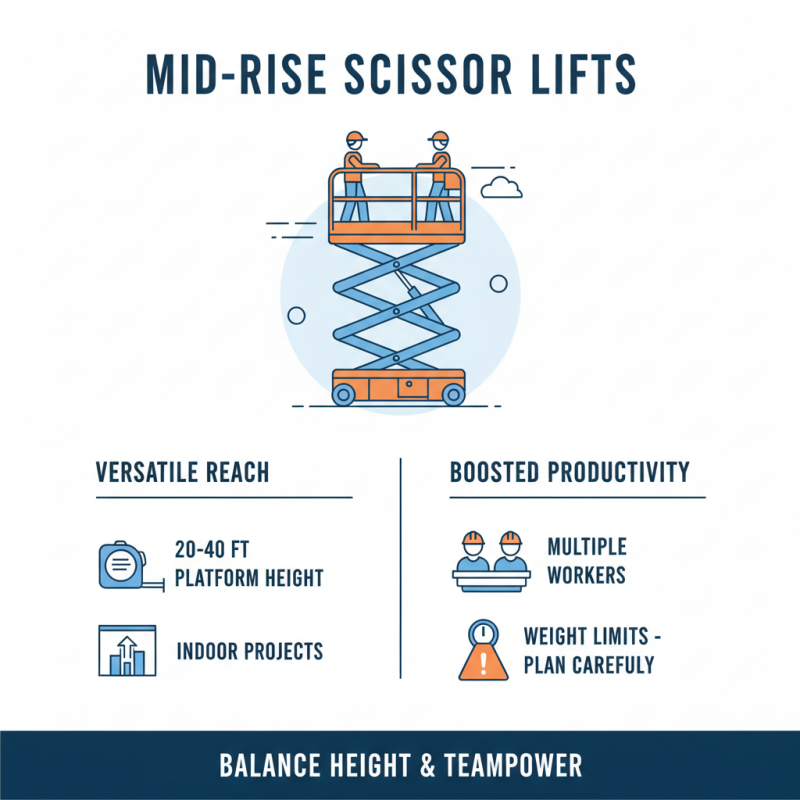

Mid-rise scissor lifts are versatile tools. They provide excellent reach without the height of full-size models. Ideal for indoor projects, these lifts often have a platform height between 20 to 40 feet. Many models allow multiple workers to operate at once. This feature boosts productivity, but also requires careful planning regarding weight limits.

When choosing a mid-rise scissor lift, consider its specifications. Look for the load capacity, which can range from 500 to 1,500 pounds. A larger capacity means more tools and materials can be transported. Pay attention to the dimensions of the lift, especially when navigating tight spaces. Compact designs can more easily fit through doorways and narrow aisles.

Using a mid-rise scissor lift effectively involves understanding its features. Familiarize yourself with the controls and safety mechanisms. Improper use can lead to accidents. Training is crucial, although often overlooked. Remember, even a small oversight can create significant hazards. Always prioritize safety and thoroughness in both selection and operation.

Choosing the right equipment for a project can be crucial. Mid-rise scissor lifts are excellent for many applications. They typically reach heights between 20 to 40 feet. This range makes them ideal for tasks like interior maintenance, electrical work, or installing fixtures. According to industry reports, nearly 30% of accidents occur during elevated work. Using the right equipment reduces risks.

Assess the specifics of your project before selecting a mid-rise scissor lift. Consider factors like weight capacity, platform size, and terrain type. Scissor lifts usually have a weight limit of about 500 to 1,000 pounds. Ensure this matches your workload requirements. You may also need to evaluate the height needed for your job. Some users find themselves struggling with equipment that doesn't quite meet their needs.

On the flip side, not all projects require a scissor lift. For smaller tasks, a step ladder might suffice. This could save time and resources. Be cautious to avoid the common mistake of choosing the lift based on availability rather than project needs. Each project presents unique challenges, and understanding these can lead to better decisions. An estimated 45% of operators feel unprepared when choosing equipment. This highlights the need for thorough assessments.

Operating mid-rise scissor lifts safely is crucial in various work environments. According to the Occupational Safety and Health Administration (OSHA), over 50,000 injuries occur each year related to aerial lifts. Proper training for operators reduces accidents significantly. For instance, using harnesses and lanyards can enhance safety. Yet, many workers still neglect these precautions.

A common oversight is not conducting thorough pre-operational inspections. Industry reports indicate that improper maintenance leads to nearly 30% of scissor lift accidents. Operators should check for hydraulic leaks, tire wear, and electrical issues before use. Ignoring these details can result in disastrous outcomes. Awareness of surroundings is essential too. Many incidents happen due to inadequate spacing, leading to collisions or tipping.

Moreover, understanding load capacity is vital. Studies reveal that exceeding the weight limit increases the risk of equipment failure. Workers often make assumptions about their loads without proper calculations. Regular training sessions can address these gaps. Despite advancements in safety technology, human error remains a major factor. Practicing vigilance can help mitigate this risk.

Regular maintenance is essential for the longevity of scissor lifts. Check the hydraulic system for leaks or damage. Even a small drip can lead to significant problems over time. Inspect the battery regularly. Corrosion can significantly reduce efficiency. Always clean the terminals to ensure proper connection.

Tires also need attention. Inspect them for wear and proper inflation. Uneven wear might signal an alignment issue. Cleaning the lift after each use can prevent rust and prolong its life. Make sure to remove any debris, especially from moving parts. Neglecting this can lead to costly repairs down the line.

Don't overlook the importance of documentation. Keep a detailed log of all maintenance activities. This practice helps track patterns in repairs. It's easy to forget when maintenance was last performed. Regularly reviewing this log can help identify recurring issues. Remember, taking small steps can prevent major headaches later on.

| Maintenance Task | Frequency | Tools Required | Estimated Time | Notes |

|---|---|---|---|---|

| Inspect Hydraulic System | Monthly | Hydraulic fluid, wrench set | 30 minutes | Check for leaks and fluid levels |

| Check Battery Condition | Weekly | Multimeter, cleaning cloth | 15 minutes | Look for corrosion and verify charge |

| Lubricate Moving Parts | Monthly | Lubricant, brush | 20 minutes | Ensure all joints are well-greased |

| Inspect Safety Features | Quarterly | N/A | 1 hour | Verify operation of alarms and brakes |

| Clean the Lift | Monthly | Cleaning solution, cloth | 30 minutes | Prevent rust and corrosion |

Transporting and storing a mid-rise scissor lift can be tricky. Proper handling is crucial to maintaining its performance. Always check the lift’s weight and dimensions before loading. Ensure your vehicle can handle the load. Use a proper ramp for safe loading and unloading. Securing the lift with straps is vital. This prevents unintended movement during transport.

When storing a scissor lift, choose a flat and dry location. Avoid areas exposed to moisture or extreme temperatures. If possible, keep the lift in a covered space. This protects it from environmental factors that can cause wear. Maintaining the battery is also important. Disconnect the battery if the lift is stored for a long time.

These practices may seem basic, yet many overlook them. Failing to secure the lift properly can lead to accidents. Storing it in a wet location may damage the circuits. Each detail matters in prolonging the life of your equipment. Taking time to reflect on these practices can help you prevent costly repairs.