Leave Your Message

Automobile scissor jacks are essential tools for vehicle maintenance, providing a compact and efficient means of lifting vehicles for tire changes and repairs. According to the Automotive Lift Institute, proper understanding of the engineering principles behind these jacks is crucial for safety and load capacity management.

With load capacities typically ranging from 1.5 tons to 3 tons, depending on the model, it is imperative for users to adhere to industry standards set forth by organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO). These standards ensure that manufacturers adhere to rigorous safety measures, helping to mitigate risks associated with improper use.

By exploring the design, functionality, and safety regulations surrounding automobile scissor jacks, users can enhance their knowledge, ensuring safer and more effective vehicle maintenance practices.

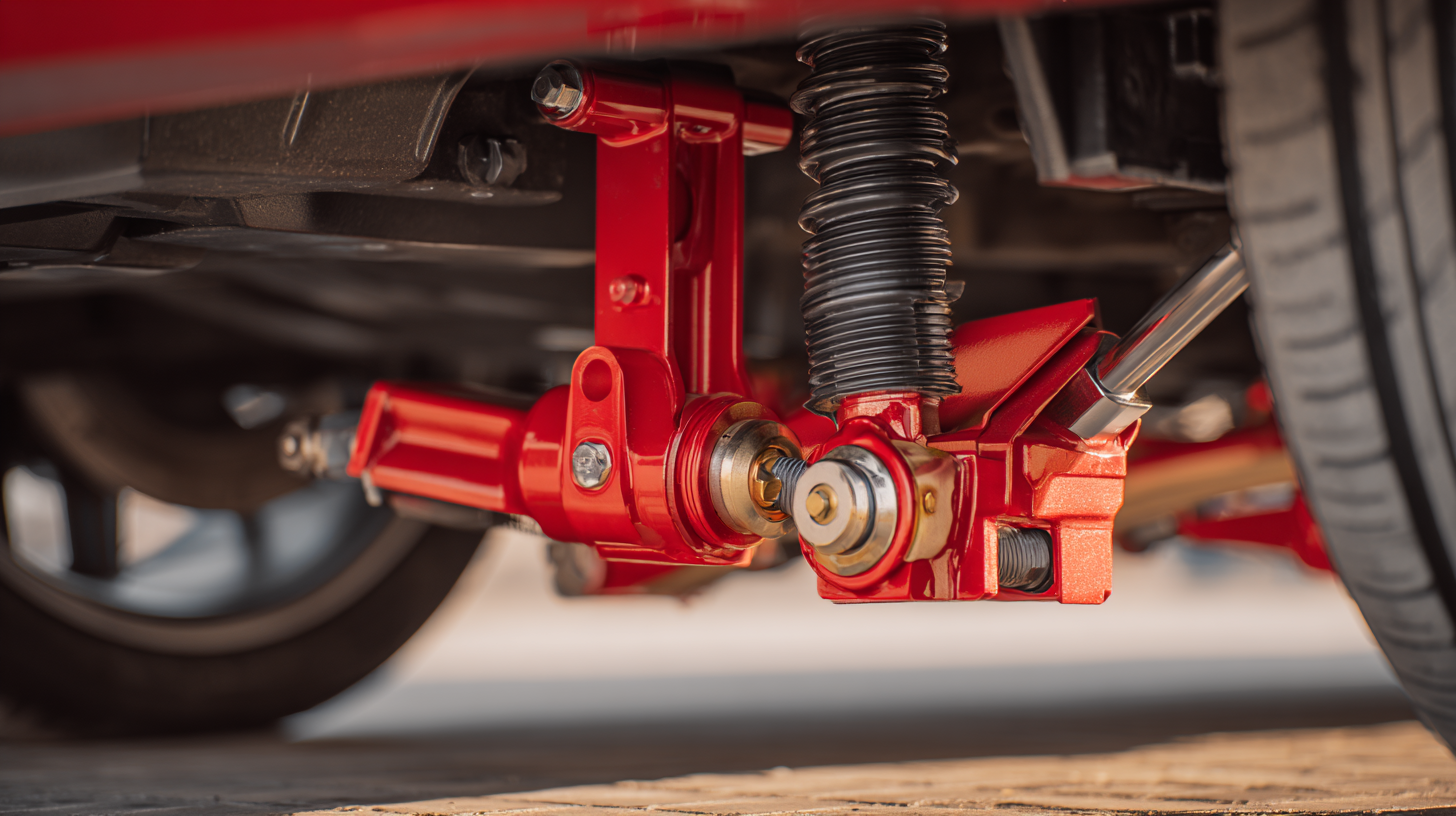

When it comes to automobile scissor jacks, understanding the different types is crucial for selecting the right tool for your needs. Typically, scissor jacks are categorized into mechanical, hydraulic, and electric variants. Mechanical jacks are manually operated and are lightweight, making them ideal for emergency situations. Hydraulic jacks, on the other hand, use fluid pressure to lift heavier vehicles with ease, offering higher load capacities. Electric scissor jacks add convenience by automating the lifting process, though they require a power source.

Tips: Always choose a jack that exceeds the weight of your vehicle to ensure safety. For occasional users, a mechanical jack is practical and cost-effective. If you're frequently working on heavier vehicles, consider investing in a hydraulic or electric model for better efficiency and safety.

When utilizing these jacks, be mindful of safety standards and proper placement. Ensure the jack is on a stable, flat surface and that you’re following the manufacturer's guidelines. Regularly inspecting your jack for wear and tear can prevent accidents and prolong its life, maintaining reliability when you need it most.

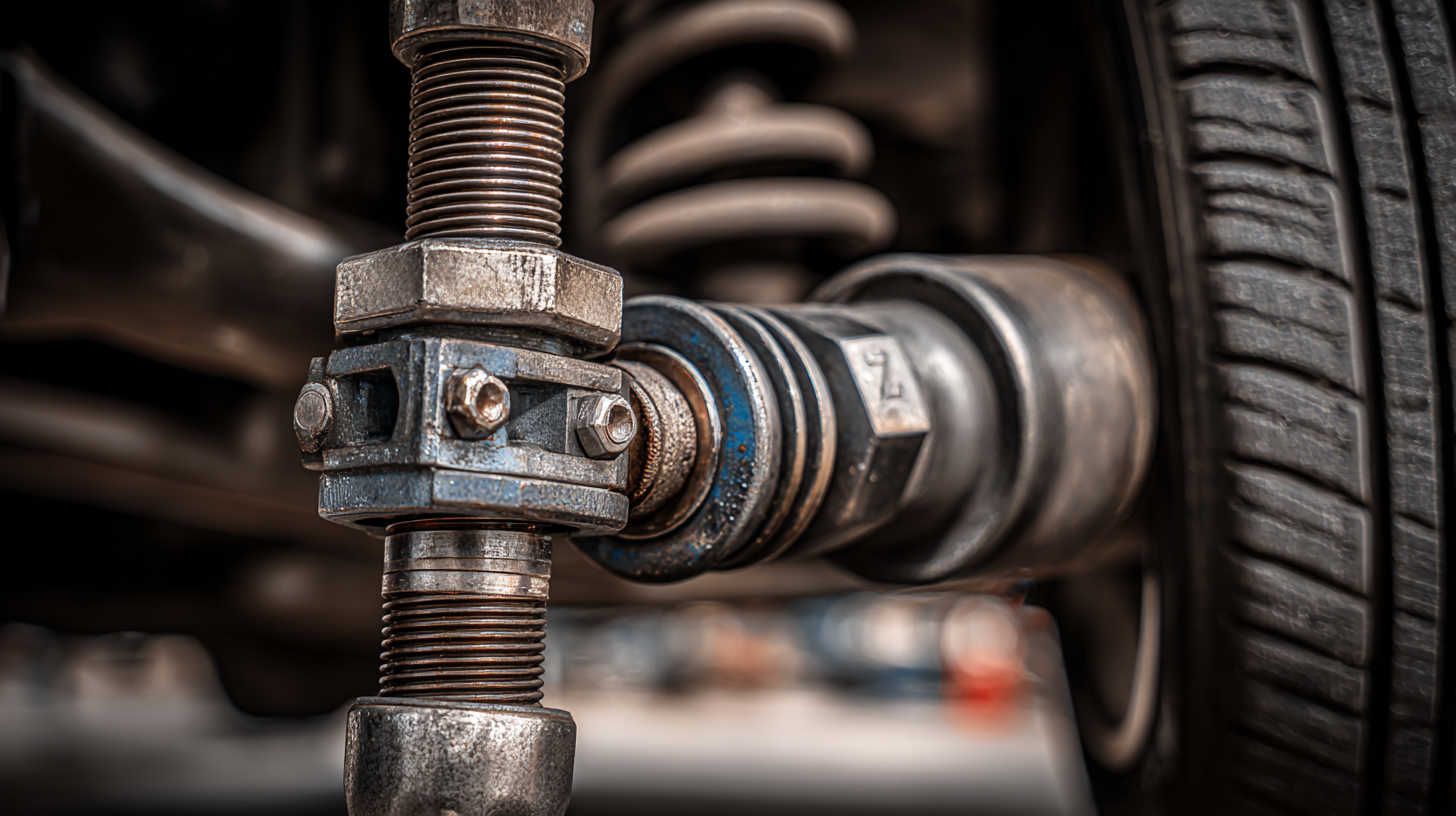

Scissor jacks are remarkable engineering feats that exemplify both functionality and safety in automotive applications. The design of these jacks relies heavily on the principles of leverage and mechanical advantage. By utilizing a crisscross pattern of arms, scissor jacks transform rotational motion into vertical lift, allowing for the effective raising of vehicles.

Understanding load capacity is crucial, as each jack is rated for a specific weight limit, often determined by the materials and design specifications. Ensuring the jack is used within its rated load capacity is essential for safety.

Tip: Always check the load rating on the jack before use to ensure it matches the weight of your vehicle.

Another key concept in scissor jack design involves the use of durable materials that can withstand heavy loads without deformation. High-quality steel or reinforced alloys are commonly used to provide the necessary strength and stability. Additionally, safety features such as locking mechanisms and wide bases improve the jack's stability while in use, reducing the risk of accidents.

Tip: Regularly inspect your scissor jack for wear and tear to maintain its safety and effectiveness. Make a habit of keeping it clean and lubricated to ensure smooth operation every time you need it.

When evaluating the load capacity of automobile scissor jacks, understanding safe operating limits is crucial for ensuring user safety and equipment reliability. Load capacity refers to the maximum weight a jack can safely lift and support. This is typically determined by the manufacturer's specifications, which consider various factors, including the jack's materials, design, and construction process. To determine these limits effectively, it is essential to assess both the static and dynamic loads the jack will encounter during operation.

In addition to manufacturer guidelines, users should conduct regular inspections of the scissor jack to identify any signs of wear or damage. Factors like rust, deformation, and mechanical wear can significantly impact load capacity. It is also important to use the jack on a level, stable surface to distribute weight evenly and reduce the risk of tipping or collapsing. By understanding these elements and adhering to the recommended load limits, users can ensure safer operation and prevent potential accidents when lifting vehicles.

This chart illustrates the load capacity of different types of automobile scissor jacks, helping users understand their safe operating limits based on maximum load ratings.

When it comes to the manufacturing of automobile scissor jacks, adhering to safety standards and regulations is paramount. The Occupational Safety and Health Administration (OSHA) has established clear guidelines for ensuring that products are designed not only to perform efficiently but also to safeguard users. These standards mandate rigorous testing and quality assurance measures to prevent malfunctions that could lead to serious injuries.

Tips for Buying a Scissor Jack: Always verify that the jack you choose meets established safety criteria, such as load capacity and durability. Look for products that have undergone third-party testing and certifications—a mark of reliability that ensures the jack can safely support the vehicle's weight. Moreover, consider the design features; a wider base can provide additional stability during use.

With the evolving landscape of vehicle manufacturing, including the rise of electric vehicles and automated systems, the importance of robust safety standards cannot be overstated. As regulators continue to refine these standards, manufacturers will need to keep pace to ensure that their products remain compliant and safe for consumer use. Staying informed about upcoming changes to regulations can also help consumers make better purchase decisions.

When using scissor jacks, adhering to best practices is crucial to ensure both safety and efficiency. According to the Automotive Lift Institute, about 13% of vehicle service injuries are linked to improper jack usage. To minimize risks, it’s essential to always operate jacks on a flat, stable surface. This helps prevent the jack from slipping or tipping during lifting, which can lead to serious accidents.

Furthermore, load capacity is a critical factor to consider. Most scissor jacks have a load capacity ranging between 1.5 to 3 tons, according to the National Institute for Occupational Safety and Health. Users should always check the manufacturer's specifications before usage, and never exceed the weight limit. Additionally, using the jack in conjunction with jack stands can provide an extra layer of safety, as they offer support and reduce the risk of collapse when working underneath a vehicle. Regular maintenance and inspections of the jack are also recommended to ensure their proper functioning and longevity, further contributing to safe vehicle servicing practices.

| Scissor Jack Type | Load Capacity (lbs) | Minimum Height (in) | Maximum Height (in) | Weight (lbs) | Safety Certification |

|---|---|---|---|---|---|

| Standard Scissor Jack | 1,500 | 4.5 | 15 | 10 | ANSI Certified |

| Heavy-Duty Scissor Jack | 3,000 | 5.5 | 20 | 15 | ISO Certified |

| Compact Scissor Jack | 1,000 | 3.5 | 12 | 8 | CE Marked |

| SUV Scissor Jack | 2,500 | 6 | 18 | 12 | DOT Approved |