Leave Your Message

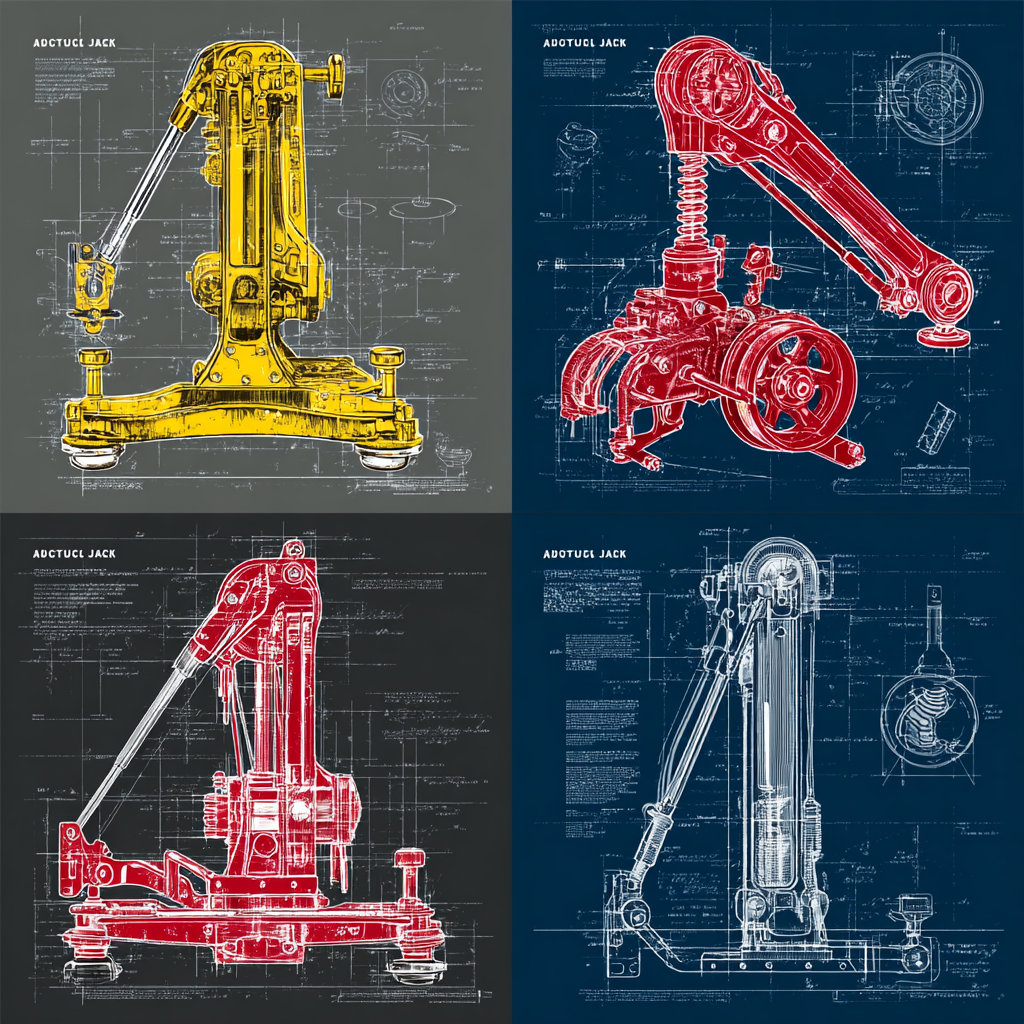

An Automatic Scissor Jack is an essential tool designed to ease the process of lifting vehicles for maintenance or tire changes. Unlike traditional jacks that require manual operation, these innovative devices utilize a motorized system to provide effortless elevation at the push of a button. This feature not only makes it more user-friendly but also enhances safety by reducing the physical strain involved in lifting heavy objects. With the growing popularity of electric and automated equipment, understanding the nuances of choosing the right Automatic Scissor Jack becomes increasingly important, especially for DIY enthusiasts and automotive professionals alike.

When selecting an Automatic Scissor Jack, various factors should be taken into account, including weight capacity, lift height, and portability. Different models cater to a range of vehicles, from compact cars to larger SUVs, making it crucial to match the jack's specifications with your vehicle's requirements. Additionally, features such as safety mechanisms, ease of use, and durability should also guide your decision-making process. As we delve deeper into the world of Automatic Scissor Jacks in this article, we aim to equip you with the knowledge necessary to make an informed choice, ensuring safe and efficient lifting for your automotive needs.

An automatic scissor jack is a mechanical device designed to lift vehicles for maintenance or tire changes with ease. Unlike traditional jacks, which require manual effort to operate, automatic scissor jacks utilize an electric motor to raise and lower the platform. This added convenience makes them a popular choice among car owners and professionals alike. Understanding how these jacks work is essential for selecting the right one for your needs.

Operating an automatic scissor jack typically involves positioning the jack beneath the vehicle and connecting it to a power source, often the vehicle's battery. Once activated, the electric motor engages, causing the scissor mechanism to expand or contract to raise or lower the vehicle smoothly.

It's crucial to consider the weight capacity, lifting height, and safety features when choosing an automatic scissor jack. These factors ensure that the jack can securely and efficiently lift your vehicle without risking damage or personal injury.

When selecting an automatic scissor jack, there are several key features to consider that can significantly impact performance and usability. First and foremost, the weight capacity is crucial; ensure that the jack can safely lift the weight of your vehicle or equipment. Typically, these jacks come with varying capacities, so it’s essential to match it to your specific needs to prevent mechanical failure during operation.

Additionally, look for the power source of the automatic scissor jack. Most models are either electric or battery-operated, and their power capabilities can influence efficiency and ease of use. A unit with a rechargeable battery might offer more convenience, especially in situations where a power outlet is not readily available. Furthermore, consider the speed of operation, as some jacks lift vehicles faster than others. Lastly, examine the design and portability of the jack, including whether it comes with a carrying case and how much space it will occupy in your vehicle. These factors can make all the difference in choosing the right automatic scissor jack for your needs.

When selecting an automatic scissor jack, it is crucial to compare different brands and models to ensure you get the best fit for your needs. According to a recent industry report from the Automotive Tool Manufacturers Association, the market for automotive lifting equipment is projected to grow by 5% annually. As more consumers and professionals recognize the benefits of automatic scissor jacks, leading brands like ProLift, Torin, and BlackBull have emerged, each offering unique features, lifting capacities, and price points.

When evaluating these products, consider the lifting capacity and safety features. For example, ProLift's automatic jack boasts a capacity of 3 tons and includes an integrated safety overload system, making it a reliable choice for heavier vehicles. On the other hand, Torin’s model is lighter and portable, ideal for emergency roadside assistance, with a capacity of 2 tons. Checking user reviews and industry ratings can also provide insight into the performance and durability of each model.

**Tips:** Always verify the jack's lifting speed and stability when fully loaded. Additionally, pay attention to the warranty offered, as a longer warranty period often signifies a manufacturer's confidence in their product's quality and reliability. Finally, factor in the weight of the scissor jack itself, especially if portability is a key concern for your usage.

When using an automatic scissor jack, prioritizing safety is essential to prevent accidents and ensure efficient operation. Always inspect the jack before use, checking for any signs of wear or damage. Ensure that the jack is placed on a flat, stable surface, as uneven ground can lead to tipping or slipping during operation. It’s crucial to use wheel chocks to prevent the vehicle from rolling while the jack is in use, providing an extra layer of safety.

While operating the automatic scissor jack, never exceed the manufacturer's weight limit, as doing so can compromise its integrity and lead to catastrophic failure. Always engage the safety lock once the desired lift height is reached, and avoid placing any body part underneath the vehicle without proper support. Following these tips will not only enhance safety effectiveness but also prolong the lifespan of your scissor jack.

This bar chart represents the usage statistics of automatic scissor jacks, including the frequency of use, safety incidents reported, maintenance frequency, and overall user satisfaction. These metrics can help in selecting the right automatic scissor jack for safe and effective usage.

Regular maintenance is essential for ensuring the longevity of your automatic scissor jack. First, it’s important to inspect the jack regularly for any signs of wear and tear. Check the hydraulic fluid levels and look for leaks in the system, as these can affect performance. Additionally, the moving parts should be lubricated according to the manufacturer's recommendations to prevent rust and ensure smooth operation.

Proper storage also plays a significant role in prolonging the life of your automatic scissor jack. Keep it in a dry environment to protect it from moisture that could lead to corrosion. When not in use, store it in a padded bag or case to prevent physical damage. Finally, familiarize yourself with the user manual, as it often contains valuable tips specific to the model you own, helping you to maintain the jack effectively and safely for years to come.